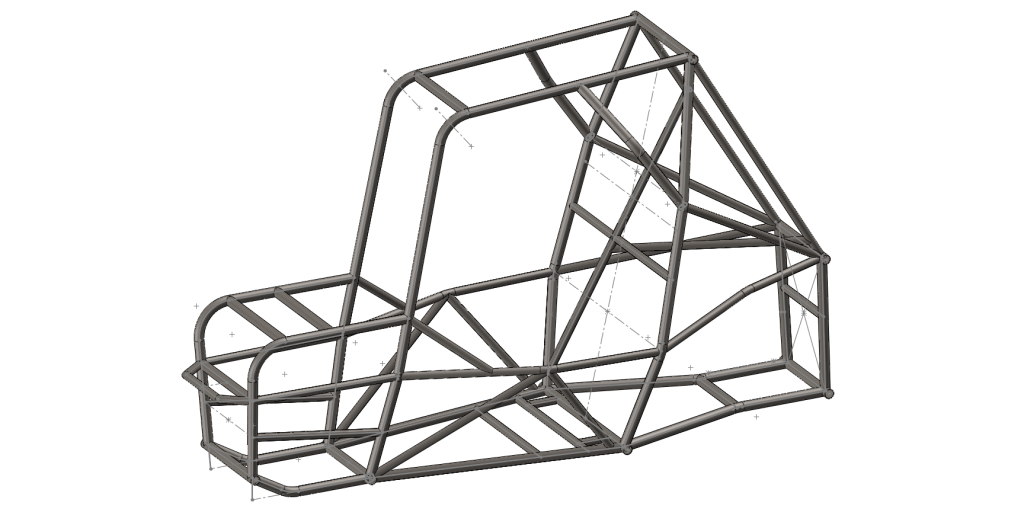

Steel Tubular Frame

Northwestern SAE Baja 2025-26 Car

Chassis Lead

Skills: Space frame design, CAD (weldments), structural FEA, preparing documentation for quotes, systems integration, leadership

A Safe, Rules-Compliant Frame

Each year, Northwestern SAE Baja designs and builds a custom off-road buggy to compete in a variety of events, most notably a 4-hour endurance race. The car is designed entirely by students, and we do the majority of manufacturing in-house.

As chassis lead, my project for our 2025-26 car is designing the steel tubular space frame chassis. The frame design prioritizes driver safety, compliance with Baja SAE rules, and inegration with all other subsystems on the car (suspension, powertrain, electronics, ergonomics).

My design objectives were to increase factors of safety in previously problematic impact cases, ensure all drivers are more comforable and leave little ambiguity with respect to rules compliance.

2024-25 Car after passing technical inspection at Baja SAE Arizona

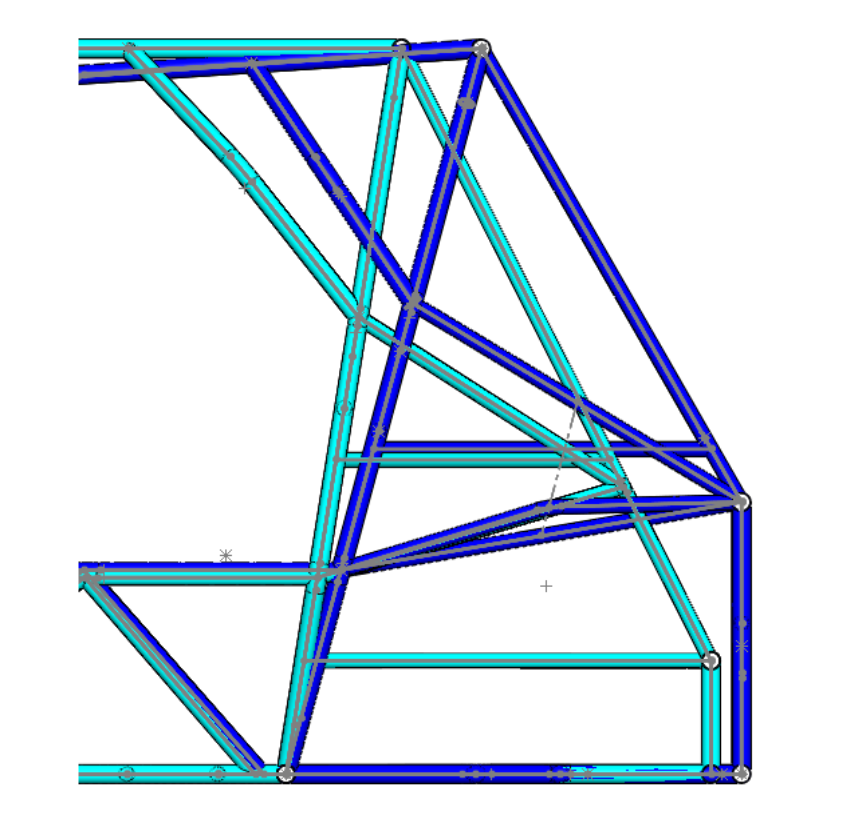

Design Highlight: Reworked Rear Bracing

A major design change I made was to rework the rear bracing structure, as our rear impact factor of safety was a razor-thin 1.01. I extended the structural triangle to the rear of the car (see right), better distirbuting the force from a potential impact through the rest of the space frame and ensuring better symmetry.

This change also increased packaging volume for powertrain and electronics components in the rear of the car by 13%, making integration, assembly, and repair easier.

Rear Bracing: 2024-25 car (teal) vs 2025-26 car (blue)

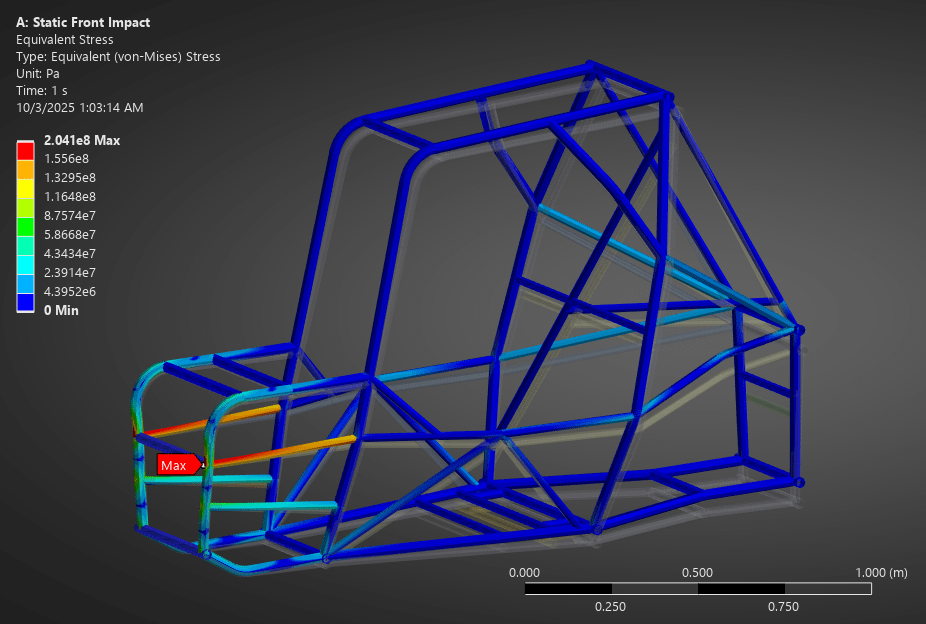

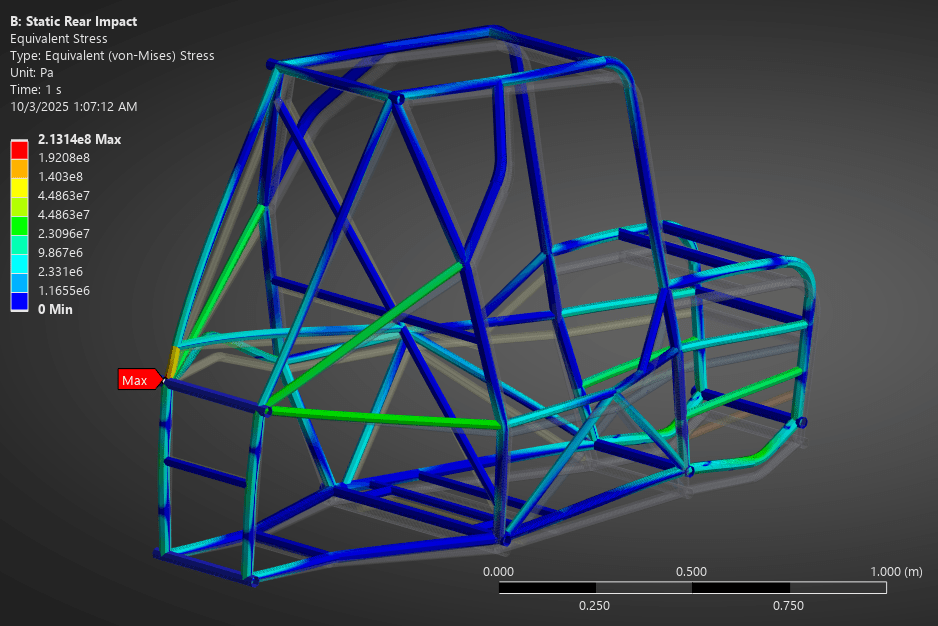

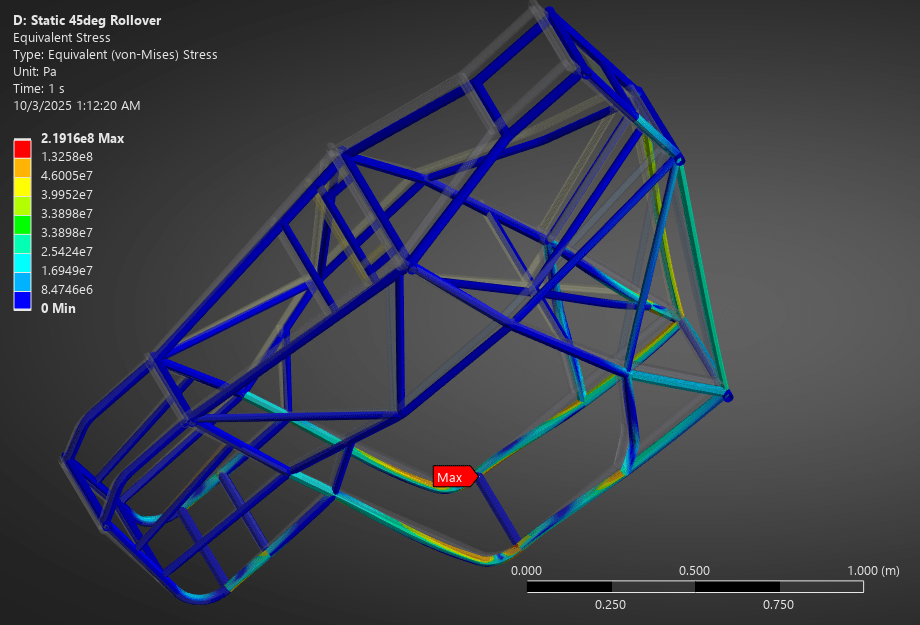

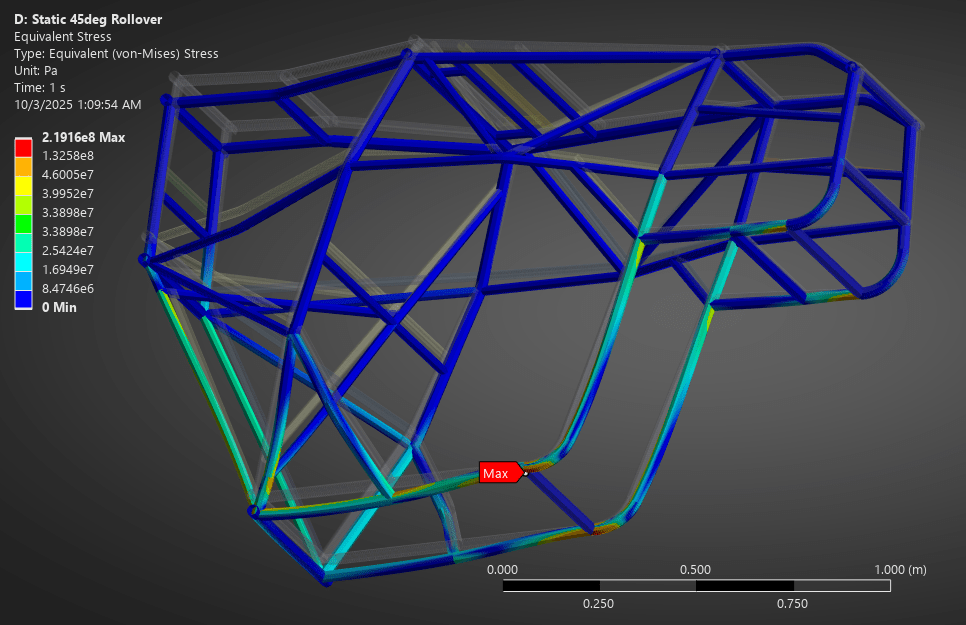

FEA

Ansys static structural analysis guided design decisions. 4 load cases approximating different crash scenarios were considered; front impact, rear impact, rollover, and an off-angle roll.

Beam meshing was used for computational efficiency, with remote loads applied to the nodes that attach the bulk of the mass (driver, powertrain, and suspension) to the frame.

Results from all 4 load cases are below.

Front Impact FEA setup with remote load

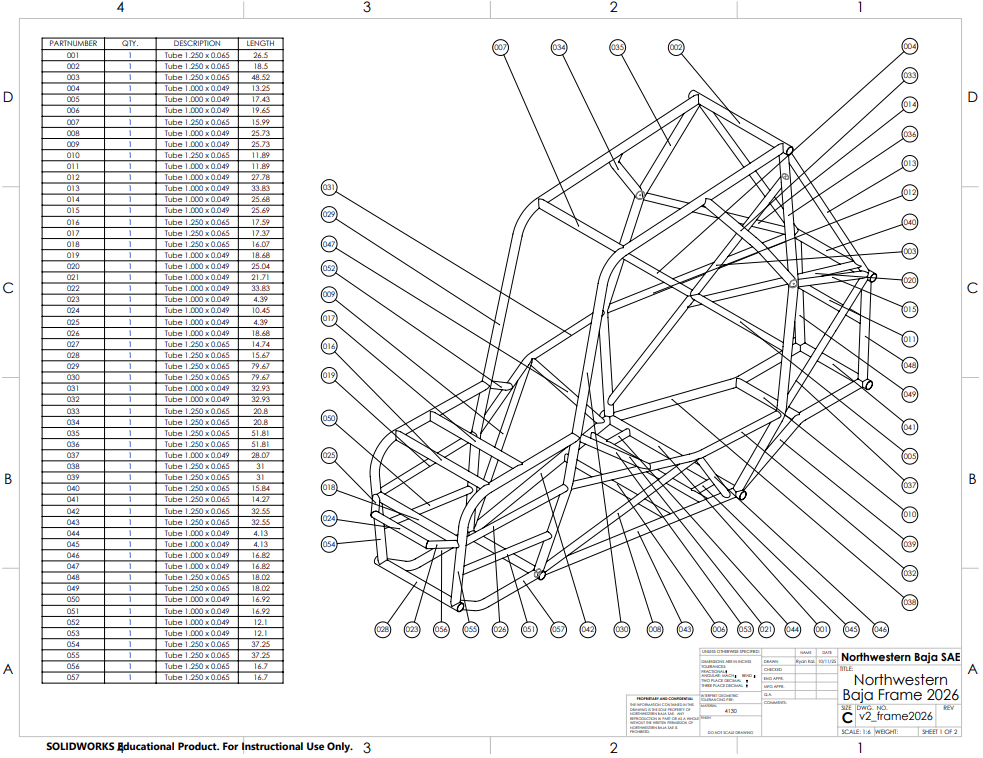

Design for Manufacturing

Without tooling to bend or notch tubes in-house, we work with a manufacturer to CNC bend and notch the frame tubing.

Throughout the design process, I made sure I was adhering to their modeling and documentation standards. I created manufacturing drawings with cut lists, a BOM, and worked with them to get a quote and coordinate manufacturing so we remained on track for our timelines.

Full Report

As part of this project I generated a design report for independent research credit. It is embedded and available for download below.