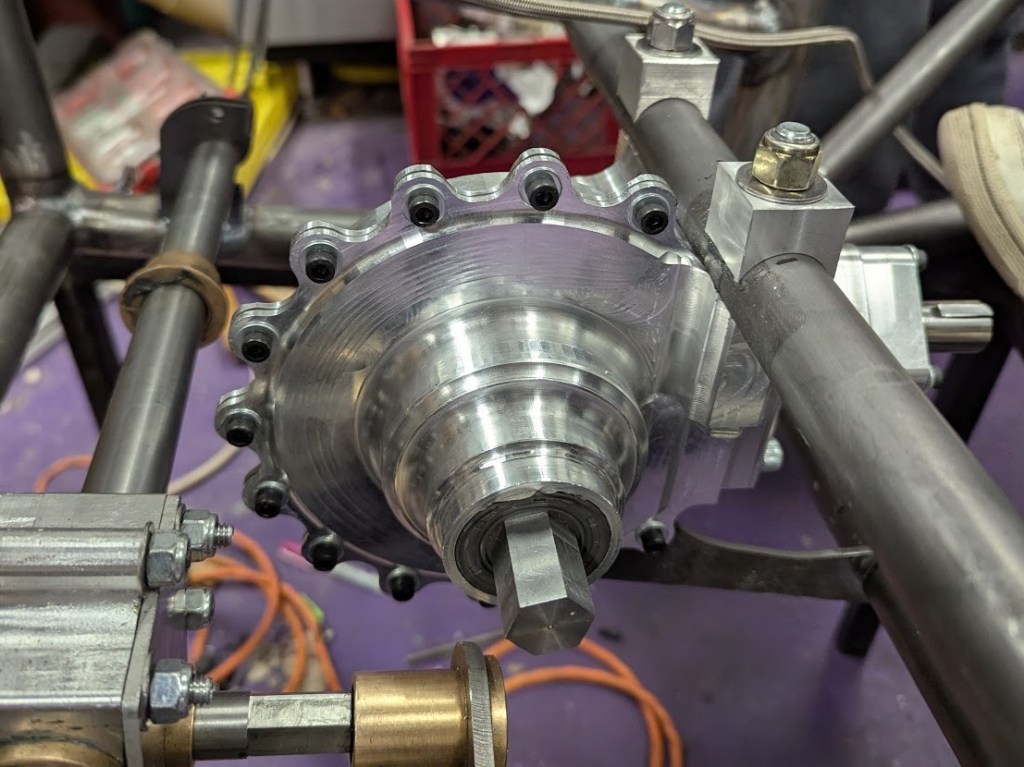

Custom 90° gearbox

Northwestern SAE Baja 2024-25 Car

Internals Design & Manufacturing

Skills: CAD, powertrain design and analysis, DFM, DFA, CNC turning, manual machining

Reliable Power to the Front Wheels

Each year, Northwestern SAE Baja designs and builds a custom off-road buggy to compete in a variety of events, most notably a 4-hour endurance race. The car is designed entirely by students, and we do the majority of manufacturing in-house.

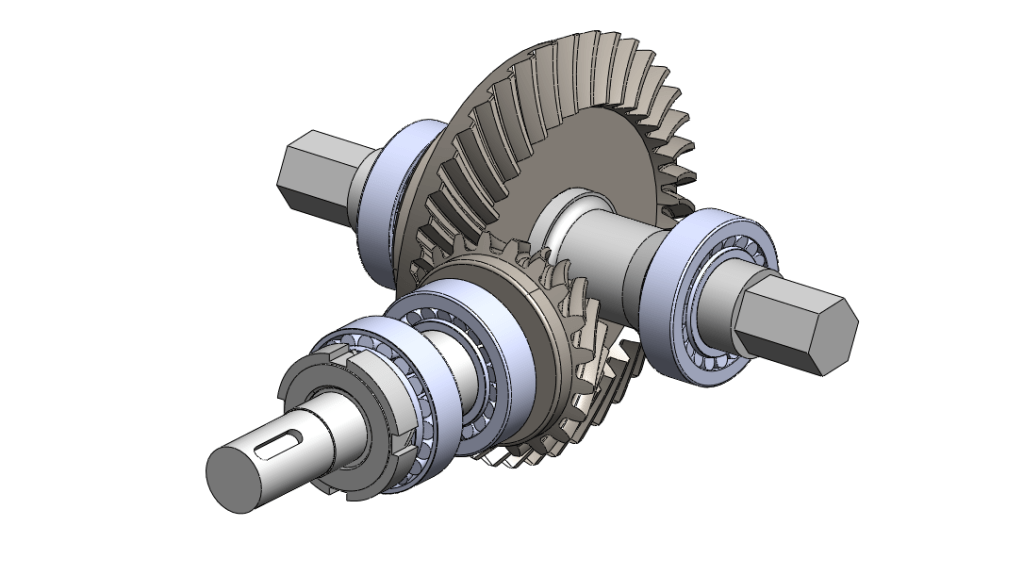

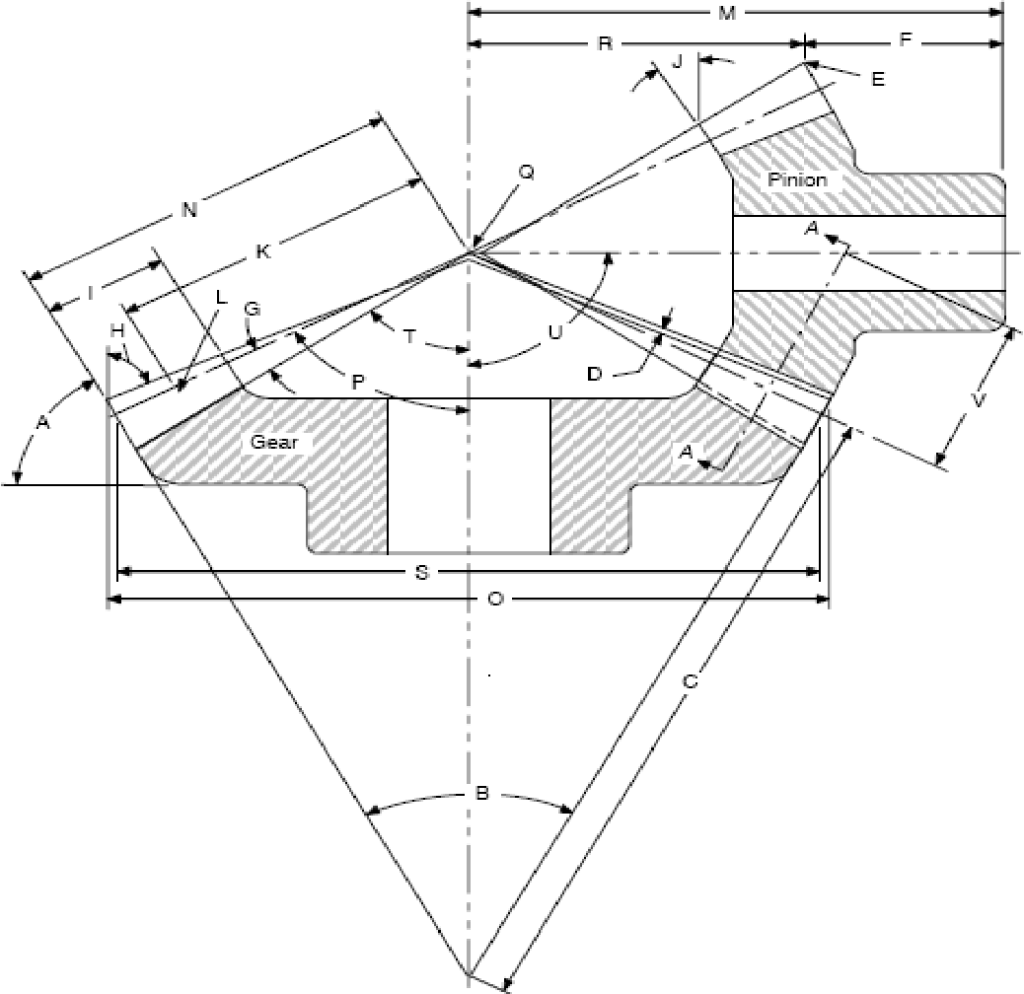

My project for our 2024-25 car is the internals (shafts, gears, bearings, etc) for a 90° gearbox that sends power from the driveshaft to each front wheel. This is the third year we have made a custom gearbox like this, but previous iterations have not had rigorous mechanical analysis (leading to failure, see right).

My main objective was to do that analysis and make design iterations accordingly, while documenting my process for future cars. I am also responsible for manufacturing the internal components.

Shaft failure at a keyway on the 2022-23 car

Textbook to Transmission

I first had to learn all about gearbox design, including shaft design and analysis, gear design, and bearing selection. I had to start this project before taking the class that covers this material, so I was responsible for learning it on my own.

We had not done proper calculations for spiral bevel gears in past years. I had to track down the ANSI/AGMA 2003-B97 standard for spiral bevel gear design and teach myself how to utilize it correctly.

Managing my calculations with a comprehensive spreadsheet helped me adapt quickly to changing design requirements and iterations.

The powertrain sub-team lead, Nicole, and other team leaders were very helpful as I learned and failed and iterated during the design process.

They were responsible for determining big-picture items for the drivetrain, and as those designs were iterated I had to adjust my design accordingly. We had a few rounds of design reviews to solidify my design.

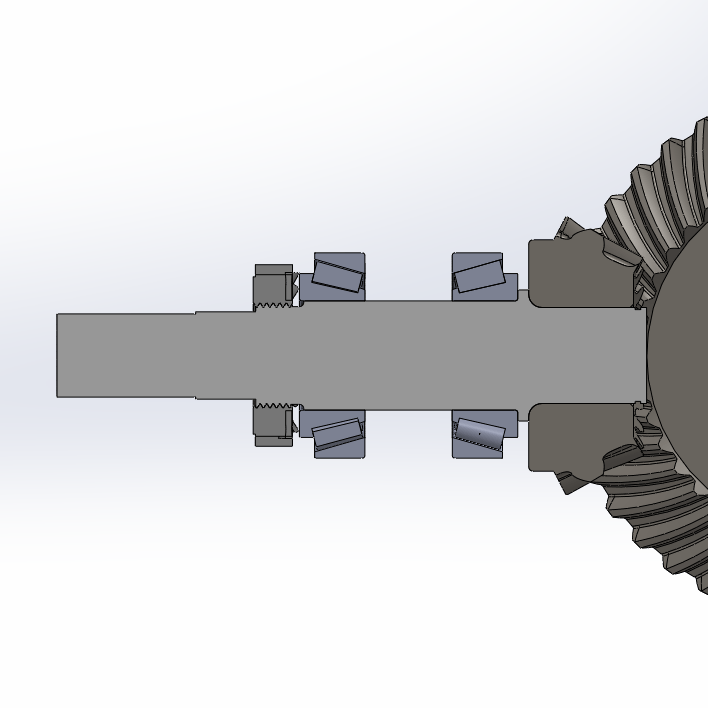

Full powertrain assembly

Reliability and durability are our primary goals, since we compete in an endurance race. The shafts and gears are designed/selected for strenuous high-cycle fatigue conditions, and all components have a factor of safety >1.3.

I also had to design for assembly, manufacturing, and serviceability. As a club we are responsible for the bulk of manufacturing, and are limited by tools available in our machine shop. I also worked closely with the rear gearbox designer and we were able to use identical bearings across both gearboxes on all but one shaft, reducing costs and improving serviceability.

Our #55 car in the pits after snapping a CVT belt

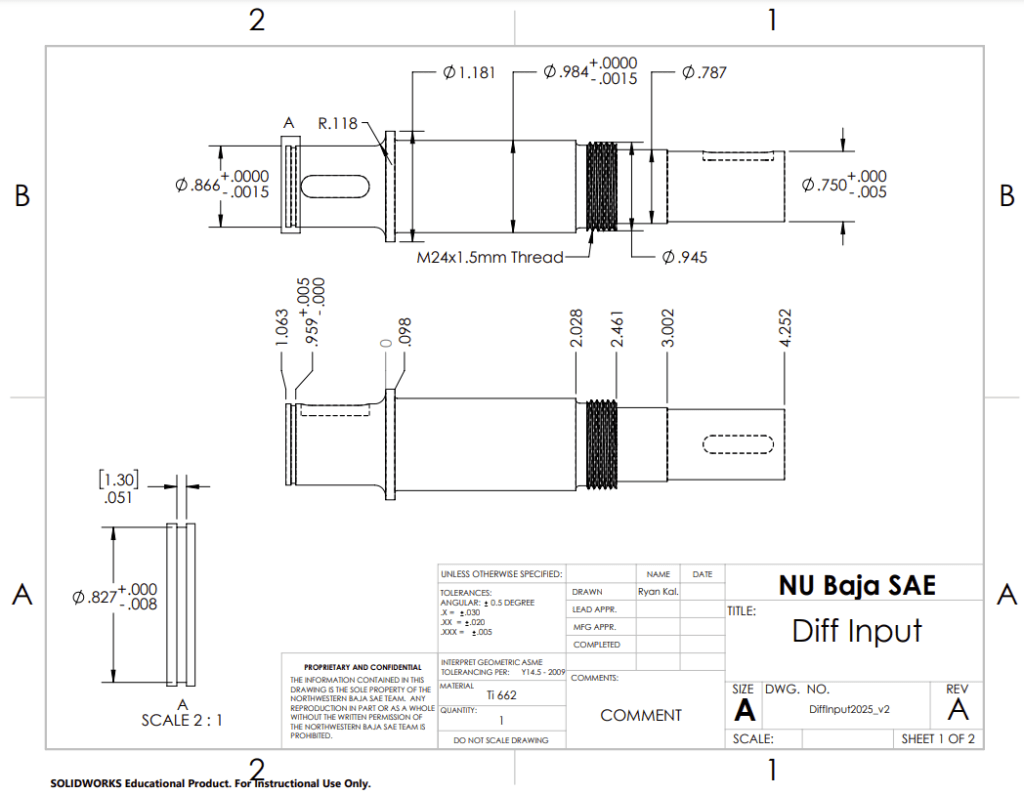

One major change this year was switching the input shaft bearings to a back-to-back configuration. This makes the gearbox more compact, making room in a typically crowded pedal box.

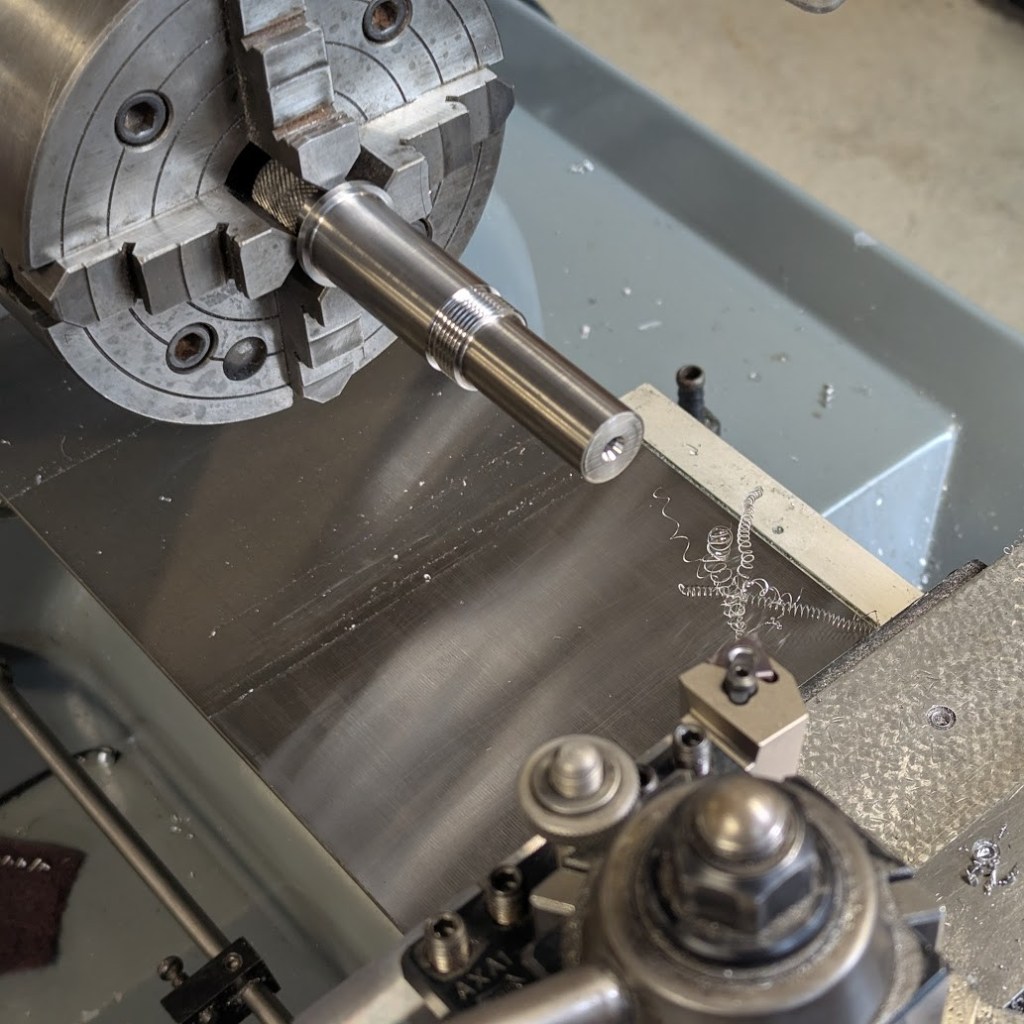

It does require the input shaft to be threaded, which adds to manufacturing difficulty. However, it also ensures better, more consistent bearing preload and easier assembly by using a locknut instead of shims.

Tomasz, another team member, was responsible for the housing design. We worked closely through the design process, making sure that our parts were compatible at every iteration.

He did a ton of work to develop CAM programs for each of his parts, and then CNC machined the housing out of 6061 aluminum.

Making it Real

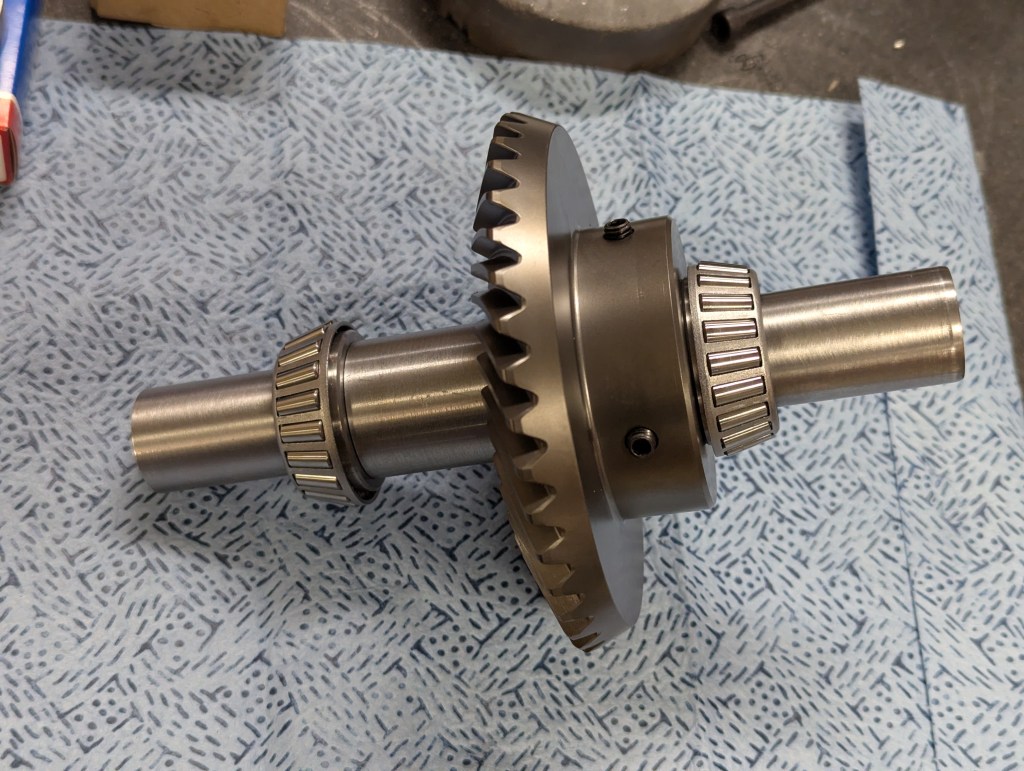

I sourced the gears and bearings and manufactured the shafts to spec with some help from my teammates.

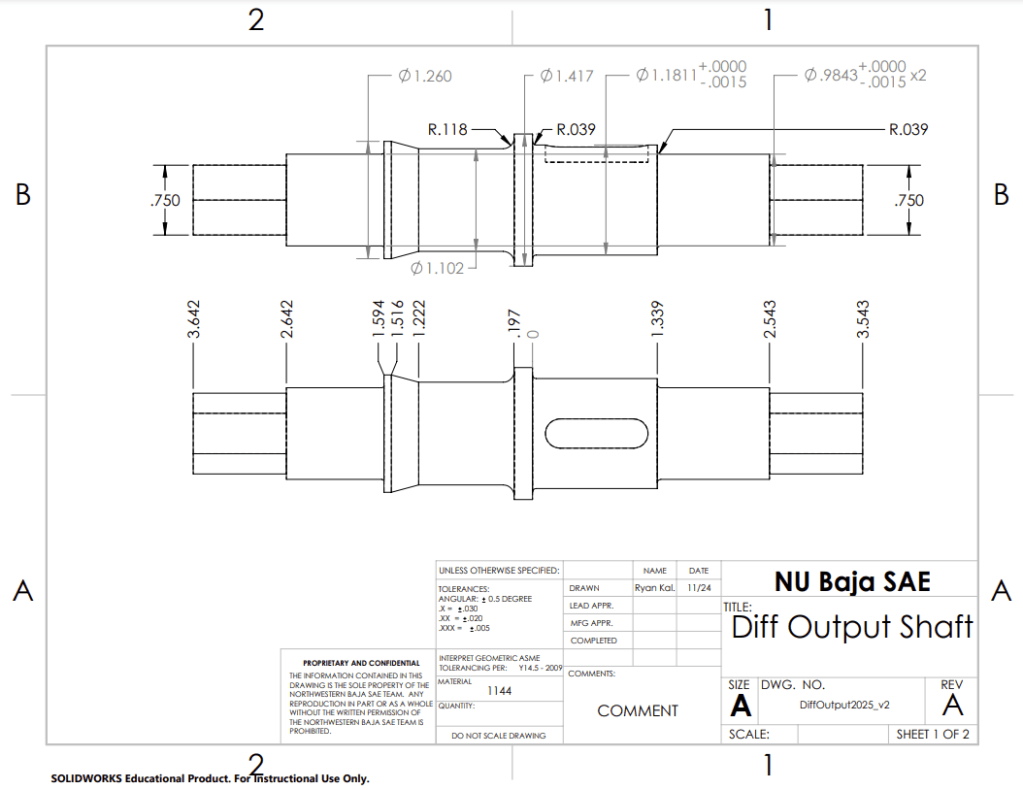

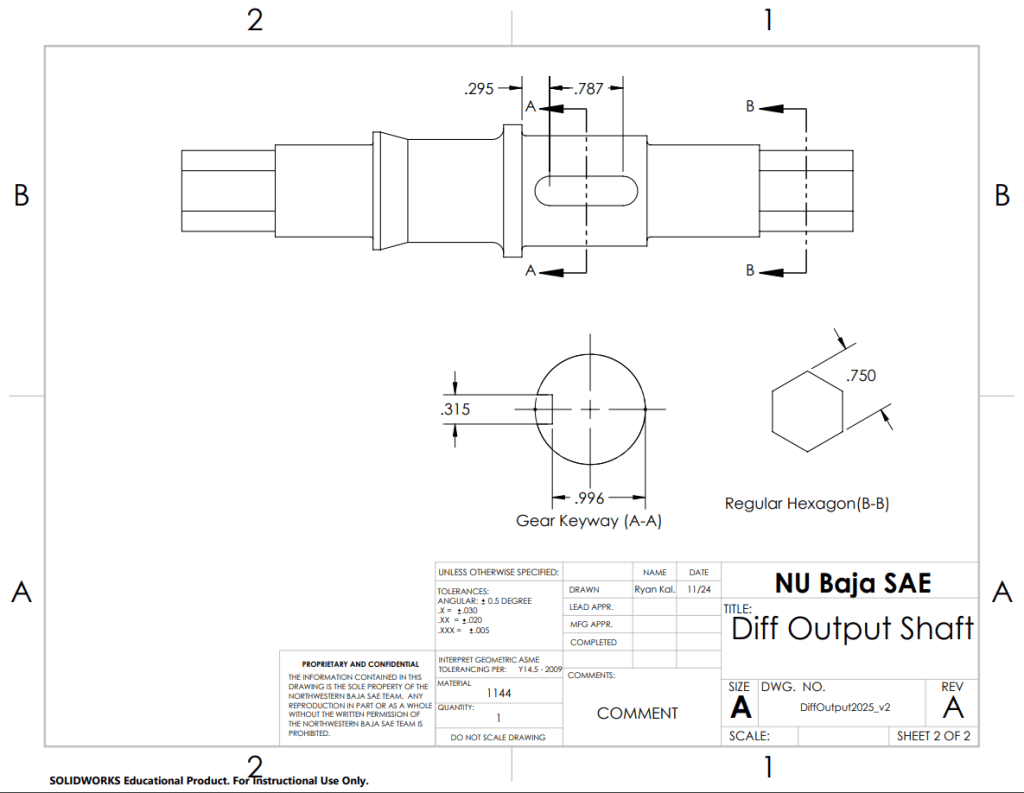

Before getting started, though, I made manufacturing drawings for both shafts.

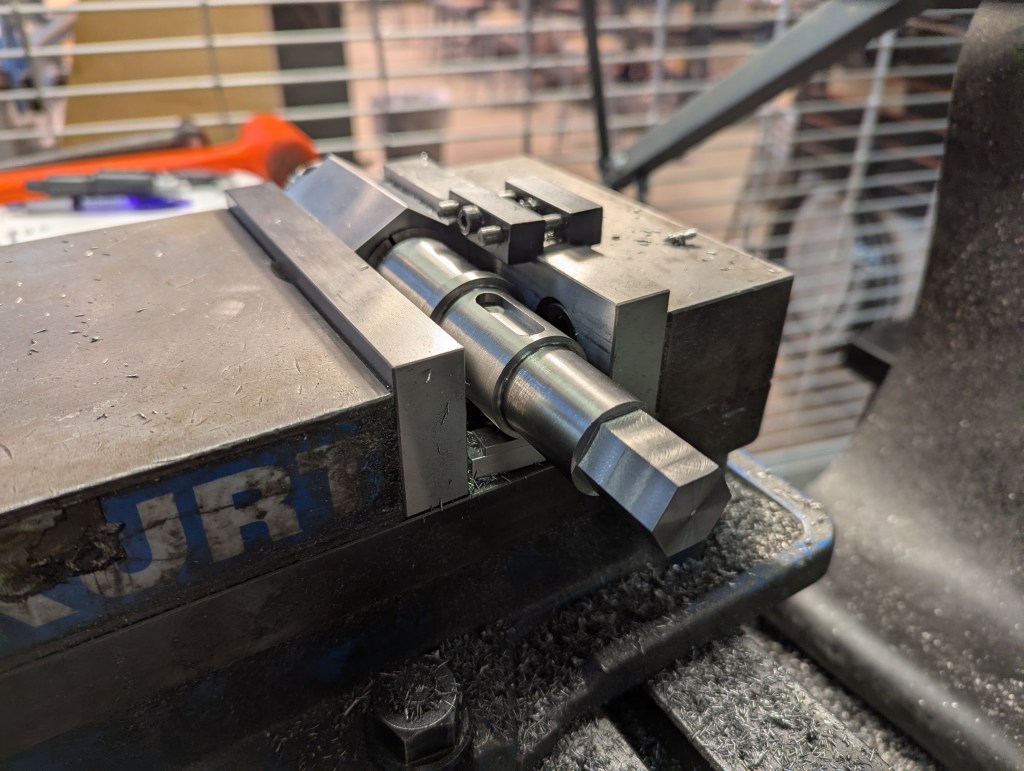

Single-point threading on the titanium input shaft

Once the internals and housing manufacturing was complete, Tomasz and I worked together to assemble the gearbox.

There were some hiccups during this process but it all went together and spins smoothly with acceptable backlash.

I learned how to design a basic gearbox, then applied and expanded my knowledge to complete internals design for a spiral bevel gearbox. I improved on previous designs by finding and utilizing resources to perform more rigorous mechanical design calculations, in addition to making my design more compact and more serviceable.

Robust, Reliable, and Serviceable

During testing days, my gearbox worked reliably without fault. Being able to remove the input section in isolation helped us quickly diagnose if anything was amiss after testing; it was around 30 minutes from when the oil was drained to being disassembled, examined, reasssembled, and reinstalled on the car.

At Baja SAE Arizona 2025, our main competition, the gearbox saw increased loads all weekend due to the failure of our torque limiter. It handled this increased load without issue during the entire competition.

It saw competition again this past October, where it continued to function as intended.

People

The people are what make Baja great. There are too many to name but in particular, Nicole, Konrad, Jared, Ryan, Maddy, Eytan, Tomasz and Arjun have all been a huge help with this project.

We do good work and we have fun doing it. It’s been amazing to see the club nearly double in size this year, which I attribute to the sense of community that we’ve built and the training and support we provide new members.