Injection Molded Snoopy

Mechanical Engineering Classwork

Skills: CAD, CAM, injection molding design, CNC machining, injection molding, metrology

Toy Project

For an injection molding class, I worked as part of a team of 3 to develop a polypropelyne Snoopy figurine.

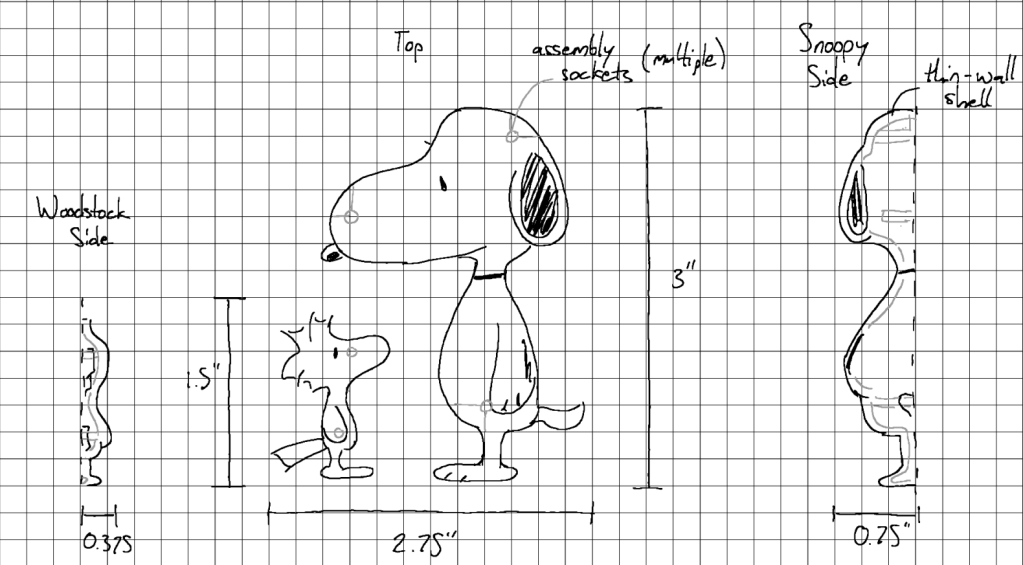

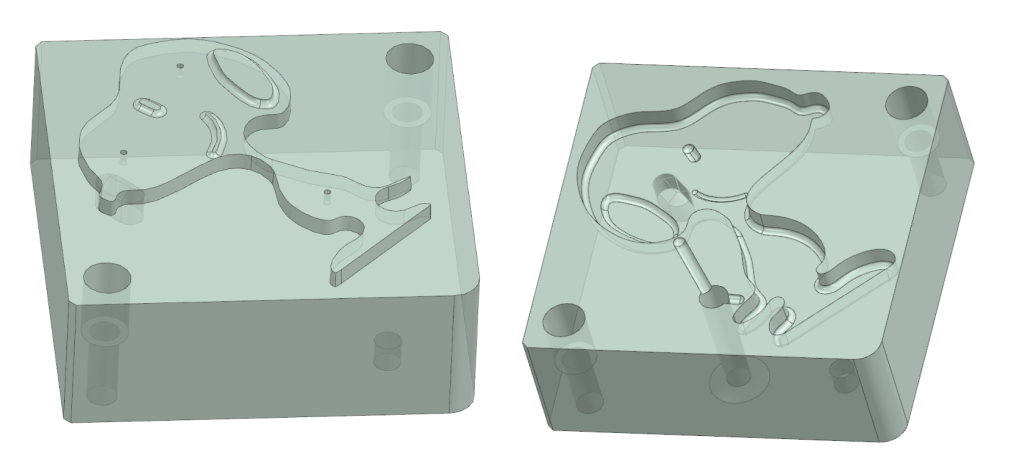

Project requirements specified the need for 2 separate parts (requiring 2 mold cavities and 2 mold cores) and assembly features to connect both parts.

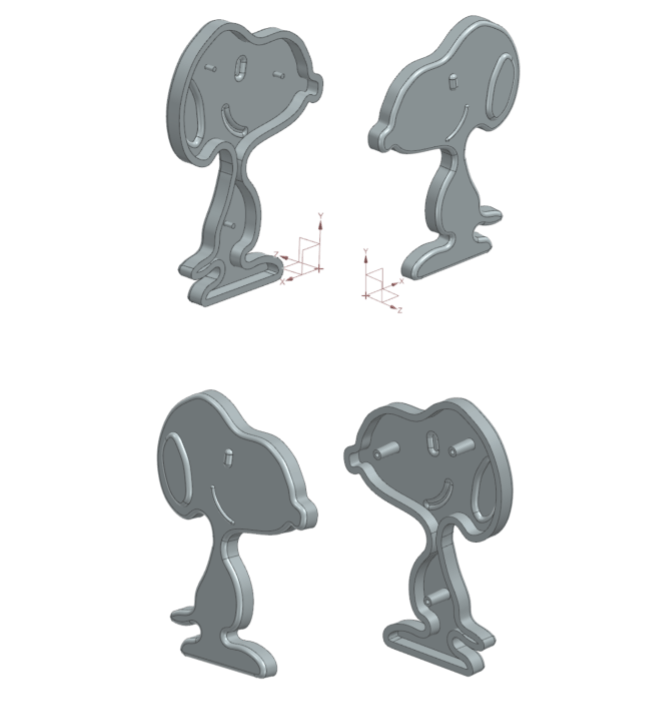

Part & Mold Design

We designed two thin-walled shells with pin and socket assembly features (left), along with corresponding molds for each half (below).

We considered machinability, injection mold features like draft, even wall thickness, and shrinkage compensation, interference fit calculations for assembly features, and runner/gate design and placement.

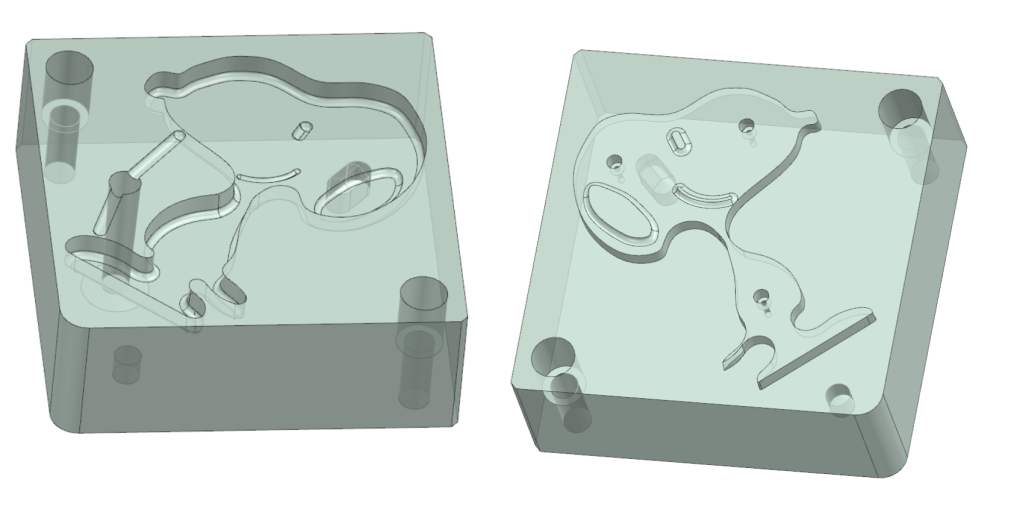

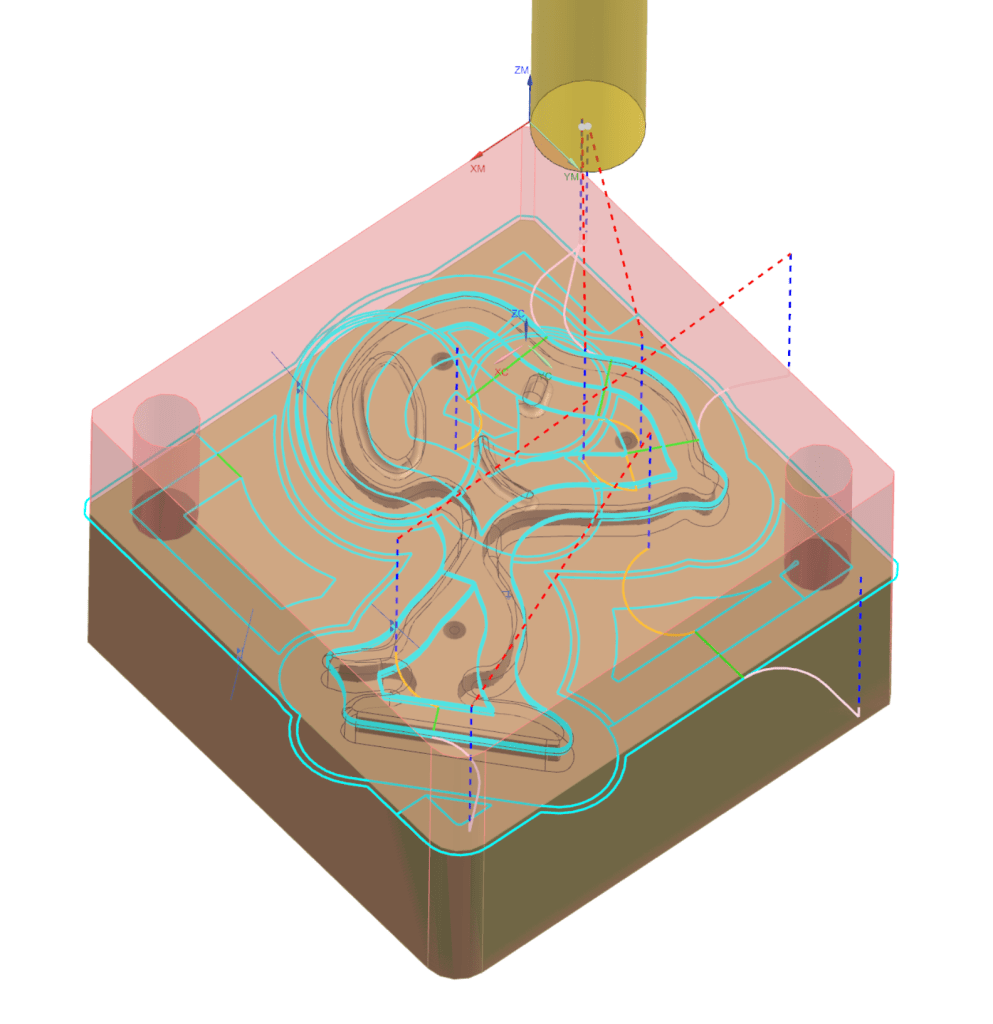

CAM Programming

Using NX CAM, we wrote a CAM program for each mold side, minimizing tool usage and machining time albeit with pretty conservative feeds and speeds.

To the right is one of the toolpaths from the CAM program for one of the mold cores.

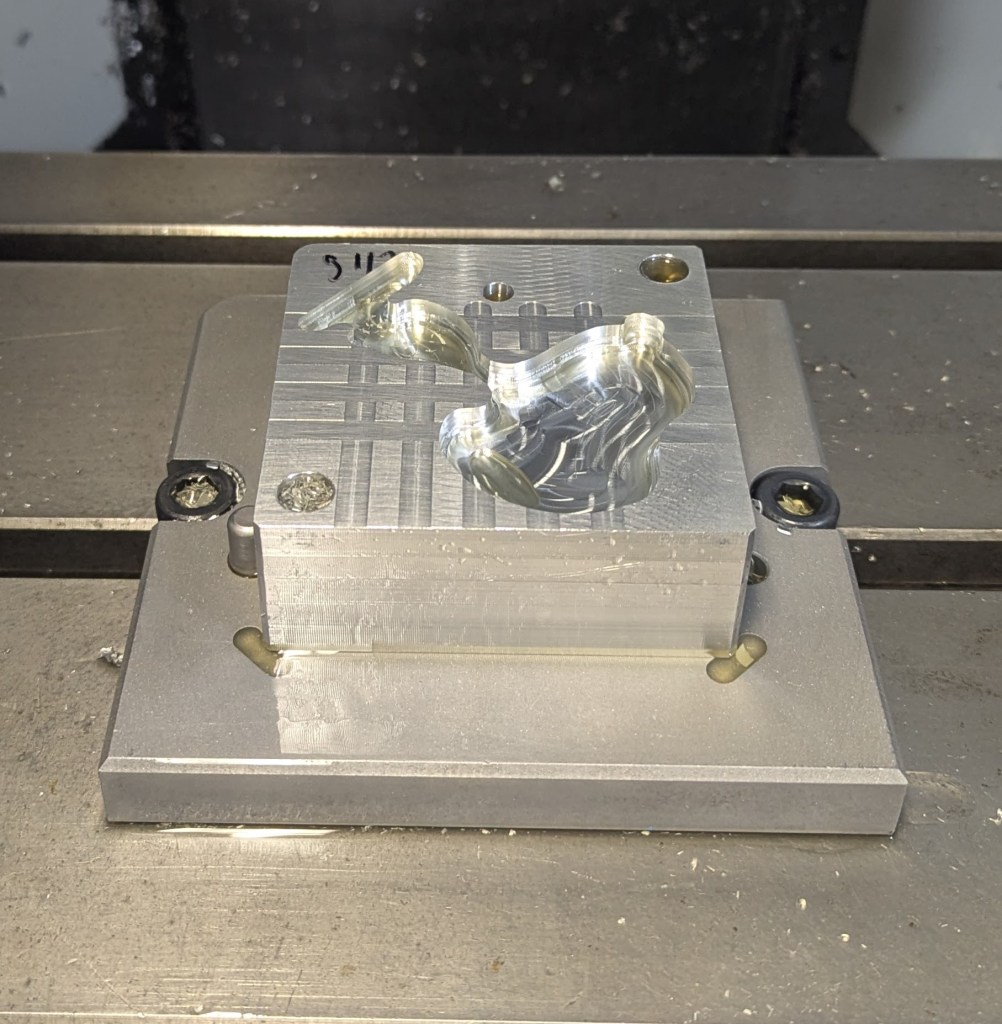

CNC Machining

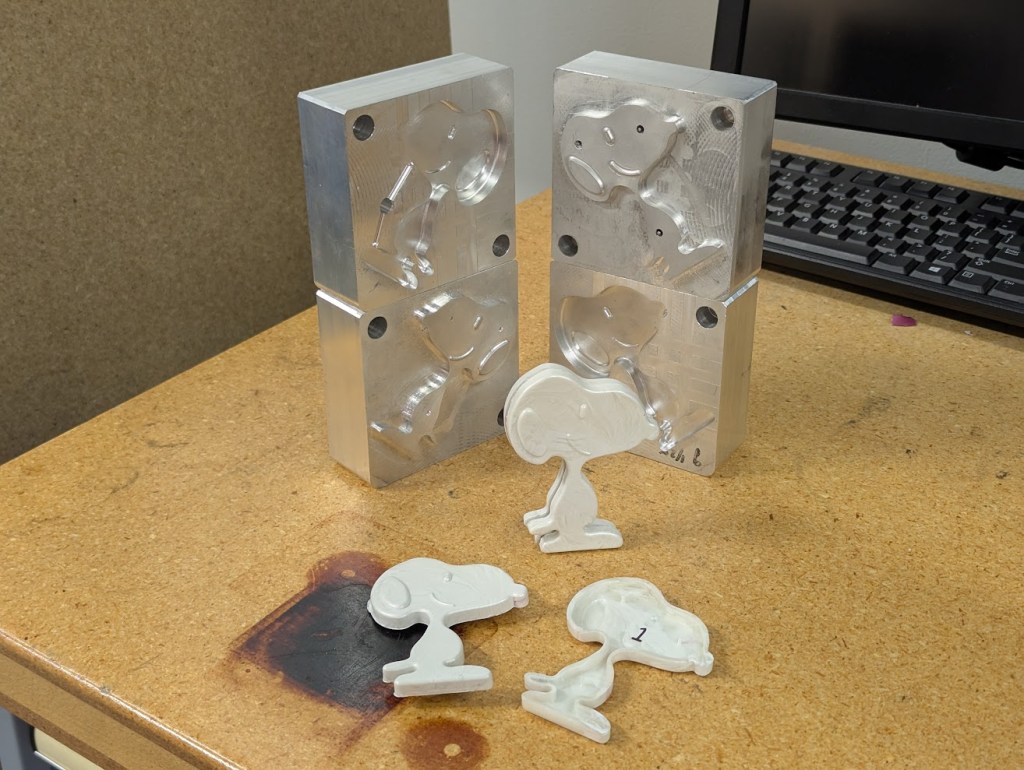

We then machined our molds from 6061 aluminum on a 3-axis Haas Super Mini Mill. Each mold came out well, with a few small defects and machining hiccups encountered along the way.

To the left is one of the cavity molds midway through machining, and below is the same cavity fully complete.

Injection Molding

Next, we injected into our molds. Polypropelyne was used for all projects in this class due to its durability when used in inteference assembly features and favorable injection molding requirements.

To the right is one of parts immediately after mold release.

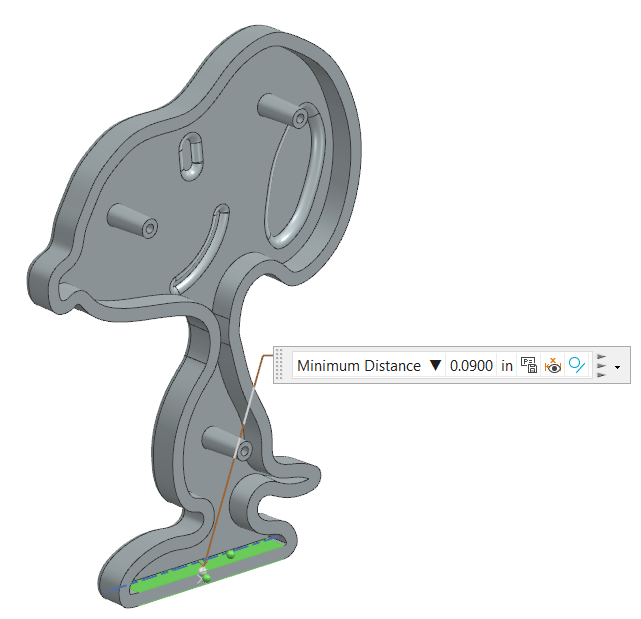

Small Run & Metrology Study

After dialing in injection parameters, we had to make a small production run of 20 assemblies. After this run, we evaluated a select dimension (left) for each example and created a run chart (below).

Final Thoughts

This project was a great learning experience to get exposure to CAM, CNC machining, injection molding, and all of the design considerations involved.

To the right are all 4 mold halves and a few of the final production run.