A CNC Challenge

For a CNC machining class, I was given complete freedom (within a 4x4x4″ blank) to create something for the final project. As a total bike nerd, I’ve thought about making a a mountain bike stem for some time and this was the perfect opportunity.

The stem on a bike connects the fork’s steerer tube to the handlebars, clamping tightly on both to make sure your steering inputs are translated to your front wheel.

Design

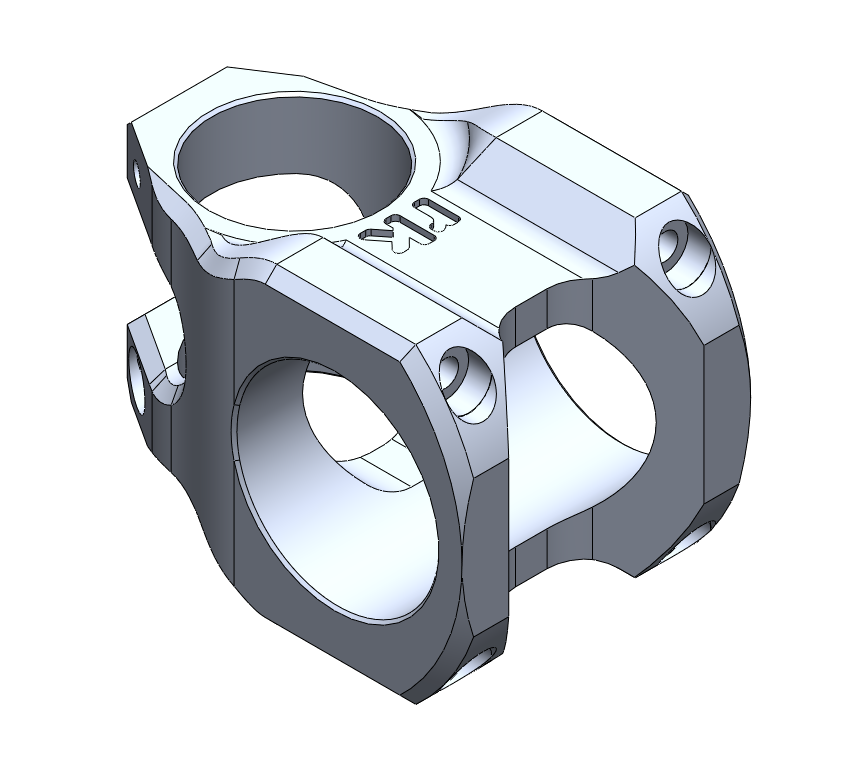

Drawing inspiration from examples on the market like IndustryNine’s A35, pictured above, I designed a short (32mm long) stem suited to my mountain bikes and riding preferences.

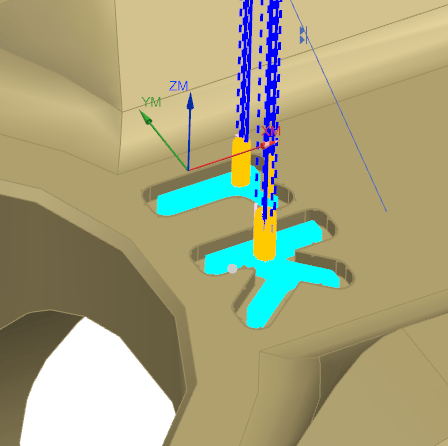

I focused more on aesthetics and manufacturability than stress analysis or weight optimization. The final design features aggressive chamfers, provisions for M4 hardware, and details like some complex surface smoothing and my engraved initials.

I ensured there were flat datum surfaces for clamping and referencing during all 5 setups, and worked to refrain from using excess tools. I will need to do some manual milling

CAM Programming

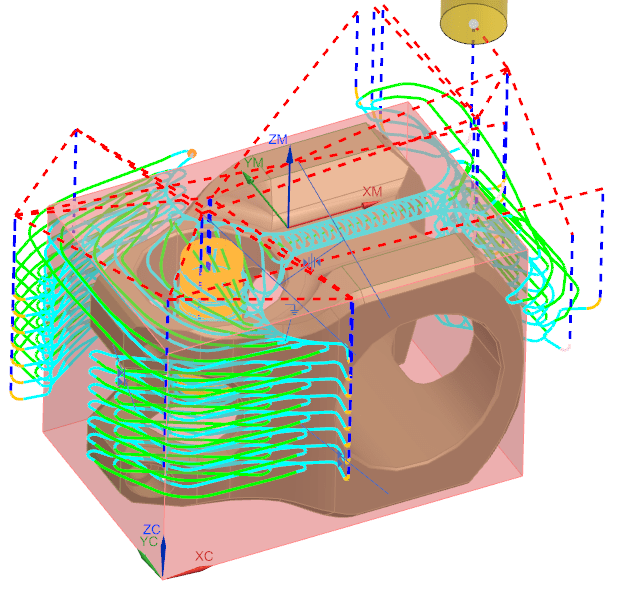

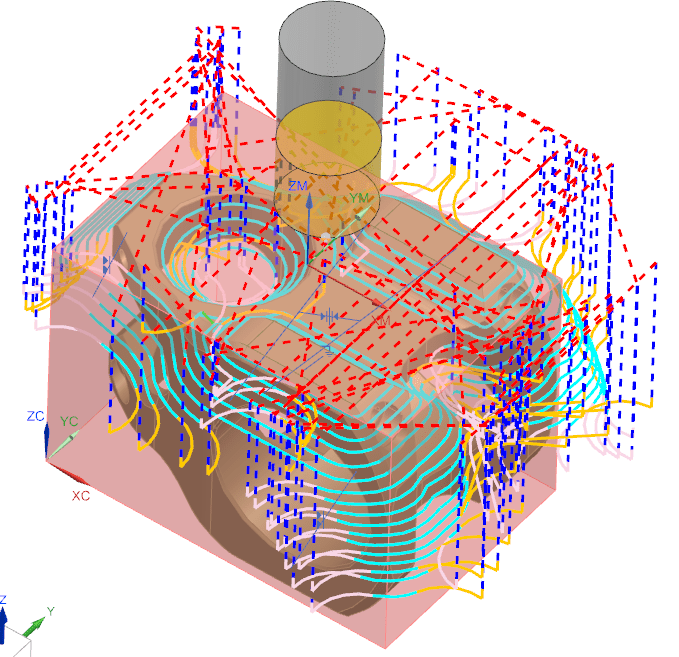

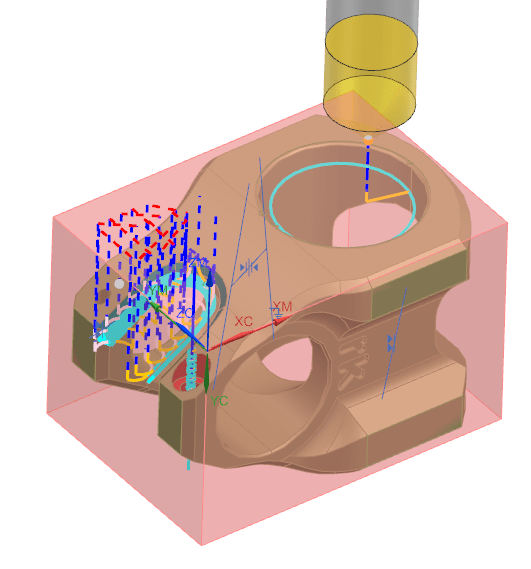

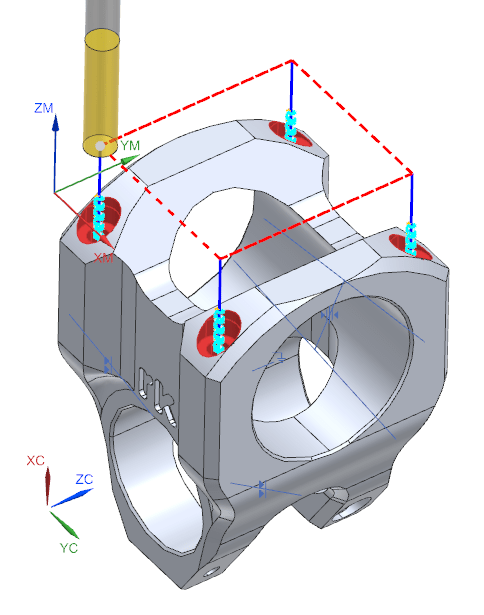

Using NX CAM, I wrote a CAM program for the 3-axis Haas machines in our shop that has 32 operations across 5 setups and utilizes 8 tools in total.

The program is not optimized for a production setting, with pretty conservative depths of cut, stepover, feeds, and speeds. It was a great learning experience figuring out how to achieve the part geometry I wanted and making sure I designed proper datums for each setup.

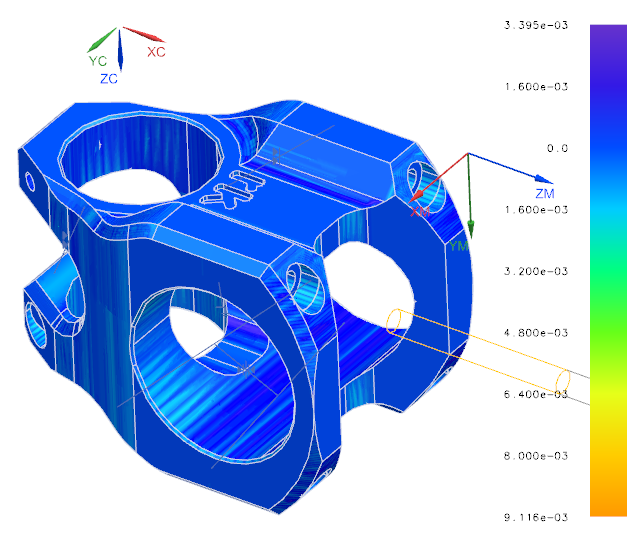

To the right and below are some of the toolpaths from the CAM program and the final predicted workpiece.

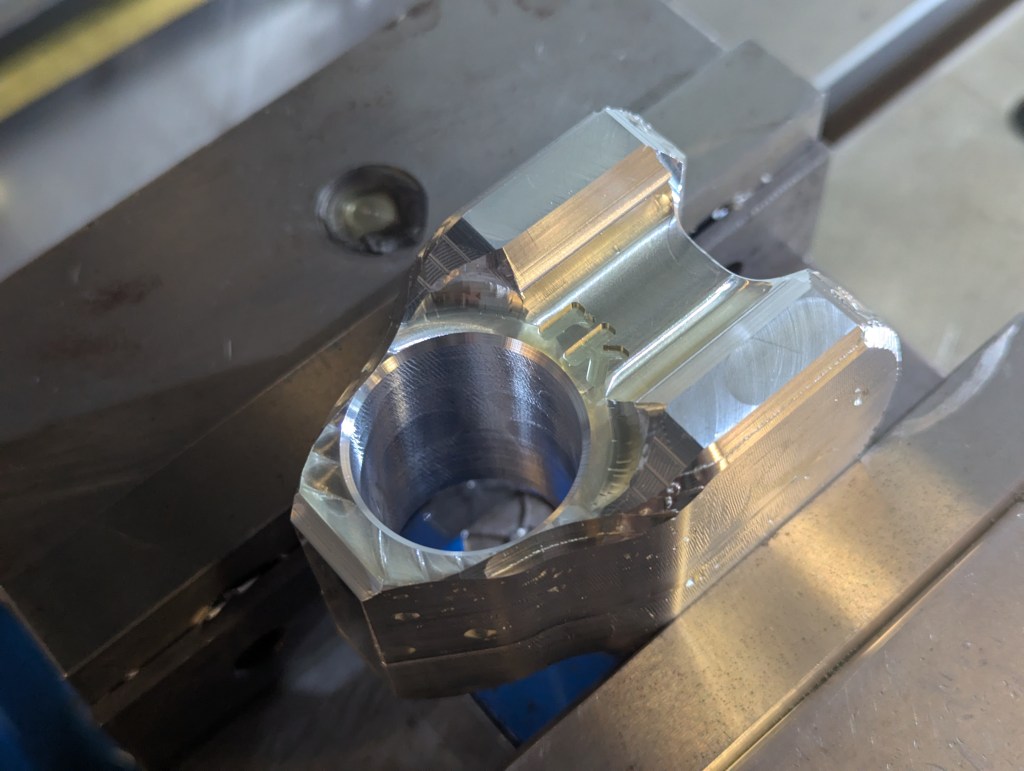

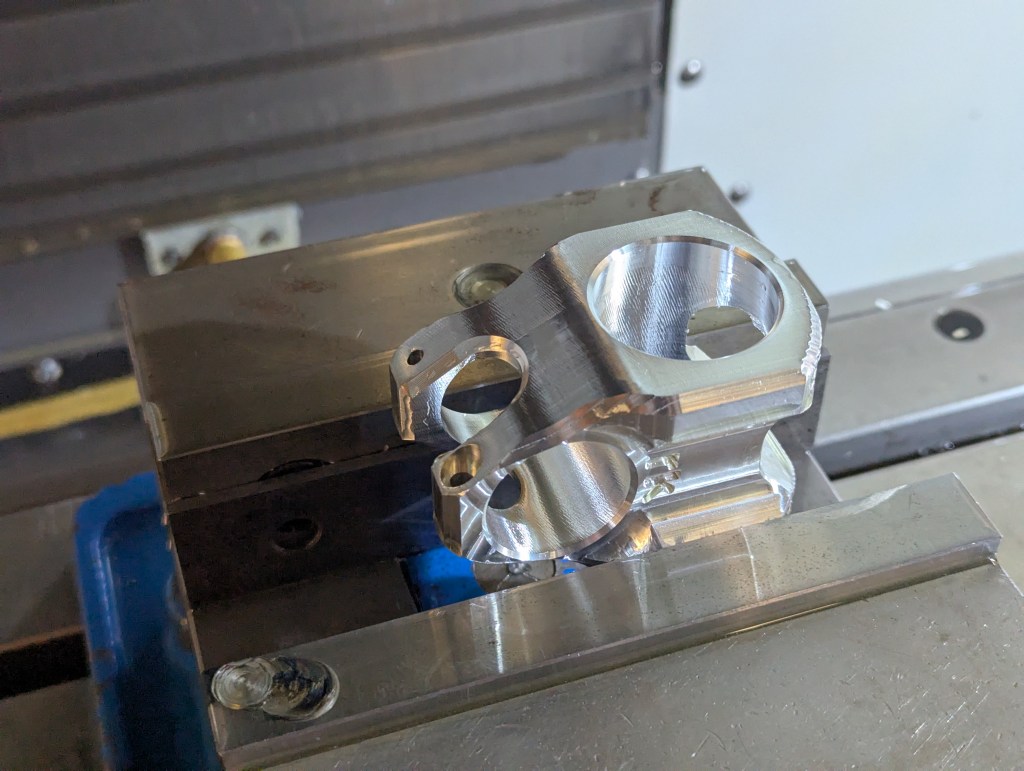

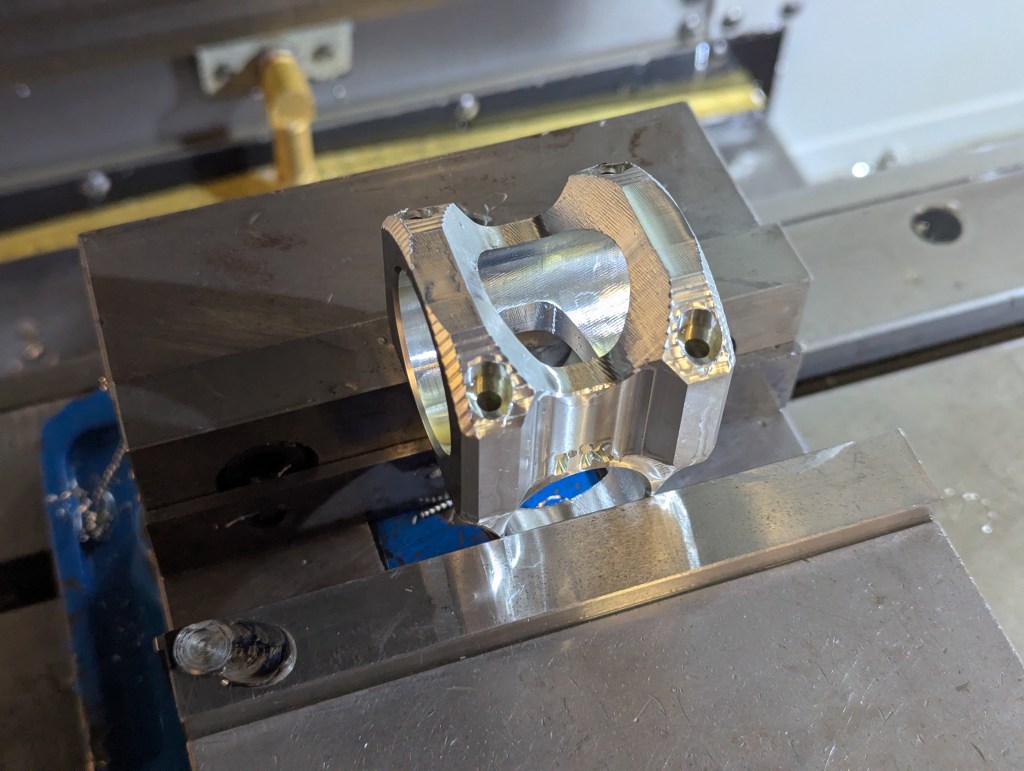

CNC Milling

After squaring up my blank, it was time to machine.

It took 11hrs in total to set up everything, run each operation, adjust fixturing and tool offsets between setups, and clean up afterwards. During that time I learned a ton more about what I would want to change if I was needing to optimize machining time.

All went smoothly, with no crashes or gouging other than one unfortunate error where I forgot to account for the tip radius of my chamfer mill. That error left some stairstep-type patterns most visible on the faceplate area, and are a good reminder for me to double check my tool geometry whenever I make something in the future.

The final part from the CNC operations is below, but still requires some tapping and slitting to be completely finished.